PE600x900 Jaw Crusher

As the core primary crushing equipment in mining operations, its performance directly impacts the efficiency and finished product quality of the entire aggregate production line. Choosing the right crushing equipment is crucial for processing challenging materials like river pebbles and granite. With 20 years of industry experience, we deeply understand our customers' core needs regarding capacity, wear resistance, and operating costs.

The BAICHY PE600x900 is a medium-sized deep-cavity jaw crusher, a classic primary crushing equipment model in crushing production lines. Its feed opening size is 600x900 mm, with a maximum feed size of up to 500 mm. The processing capacity is adjustable between 50-180 tons per hour, and the discharge size can be adjusted from 65-160 mm. This model features a robust structure and an optimized cavity design, making it particularly suitable for coarse and medium crushing of various ores and rocks with compressive strength not exceeding 320 MPa, and especially adept at processing high-hardness materials such as river pebbles, granite, and basalt.

| Key Words | River Stone/Granite Crushing Equipment |

|---|---|

| Product Model | Jaw Crusher |

| Feed Size | ≤500mm |

| Motor Power | 55kw |

| Capacity | 90-180t/h |

| Core Advantages | Deep cavity design |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Why is the PE600x900 the ideal choice for crushing river pebbles and granite?

1. Excellent Wear Resistance and High-Strength Structure: The movable jaw, fixed jaw, and frame are all made of high-strength manganese steel, and key components undergo special heat treatment, significantly extending the wear life of the equipment when crushing highly abrasive granite and river pebbles, reducing maintenance frequency.

2. Deep Cavity Crushing and High Capacity: The unique cavity design not only increases feeding capacity and crushing ratio but also creates effective layered crushing, resulting in better finished product particle shape, lower flaky content, and stable and efficient production capacity.

3. Reliable Operation and Easy Maintenance: The flywheel design effectively balances inertia, ensuring smooth operation. The centralized lubrication system and larger bearing specifications ensure the reliability of the equipment under heavy loads. Safety protection devices such as toggle plates automatically break when encountering unbreakable iron pieces, protecting the core of the main machine.

4. Energy-Saving and Efficient: Using optimized meshing angles and motion parameters, it achieves higher crushing efficiency at the same power, lower unit energy consumption, and effectively reduces long-term operating costs for users. 5. Wide Applicability: Not only is it a powerful tool for river pebble crushing and granite crushing, but it is also widely used in primary crushing operations in various fields such as mining, metallurgy, building materials, highways, and railways.

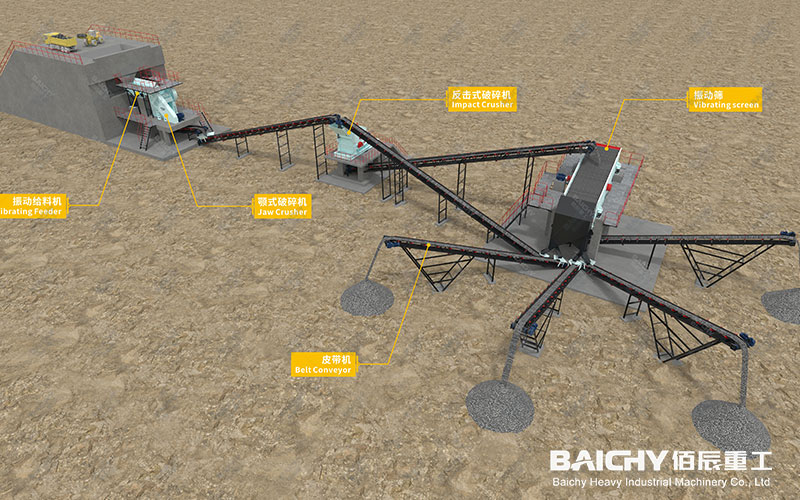

Stationary crushing production line

At a large-scale green aggregate base in China, the customer uses river pebbles from the riverbank as the main raw material, requiring a production capacity of 150 tons per hour, with the finished product used for high-grade commercial concrete. We configured a core production line for them, centered around the BAICHY PE600x900 jaw crusher as the primary crushing equipment. Since its commissioning, the equipment has been running stably. Despite the challenges of the complex composition and high abrasiveness of the river pebbles, the jaw plate lifespan exceeded the customer's expectations, the overall production line produced uniformly sized aggregate, and the production capacity fully met the requirements, earning high praise from the customer and leading to subsequent orders.

Jaw Crushing Plant

An efficient crushing production line requires not only excellent primary crushing but also perfect coordination of supporting equipment. Based on the typical configuration of the PE600x900, we recommend:

* Secondary Crushing Equipment: PYB/PYD series spring cone crushers or single-cylinder hydraulic cone crushers, used for medium and fine crushing, processing semi-finished products from the jaw crusher to obtain smaller aggregate sizes.

* Sand Making and Shaping Equipment: VSI series vertical shaft impact crusher (sand making machine), used for sand making and stone shaping of river pebbles and granite, producing high-quality manufactured sand.

* Auxiliary Equipment: GZD series vibrating feeders, 2YK/3YK series circular vibrating screens, belt conveyors, etc., to form a complete and automated aggregate production system.

Frequently Asked Questions (FAQ)

Q1: What is the average service life of the jaw plates when processing river pebbles with the PE600x900?

A1: This depends on the SiO2 content (abrasiveness) of the river pebbles and the production volume. In our typical customer cases, under medium abrasive conditions, the lifespan of a single set of jaw plates (moving jaw + fixed jaw) is usually between 80,000 and 150,000 tons of processed material. We offer jaw plates made of various materials (such as Mn13, Mn18, etc.) to suit different working conditions.

Q2: The maximum feed size of the equipment is 500mm. Does this mean that 500mm river pebbles can be directly fed into the machine?

A2: Theoretically, yes, but to protect the equipment and achieve optimal efficiency, we recommend pre-screening and controlling the raw materials using a front-end grizzly screen or vibrating feeder. This will remove or pre-process oversized or elongated stones exceeding 500mm, ensuring that the material entering the crushing chamber is uniform and continuous in size.

Q3: Compared to similar products, what are the core advantages of BAICHY's PE600x900?

A3: Our 20 years of manufacturing experience are reflected in the details: a more scientific design of the movable jaw assembly results in a more stable motion trajectory; the selection of higher-quality bearing brands and sealing structures ensures the long-term stability of the main machine; and a comprehensive quality control system from raw materials to finished products ensures that every piece of equipment can withstand harsh working conditions such as granite crushing.

Q4: Can you provide production line design and installation guidance?

A4: Absolutely. As a total solution provider with 20 years of experience, we not only provide inpidual machines but also offer professional production line process design and equipment selection based on your specific raw materials, site, capacity, and finished product requirements. We will also dispatch engineers for installation guidance and commissioning until the production line is successfully put into operation.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.